Electron beam drilling with SST electron beam machines

The drilling depth effect

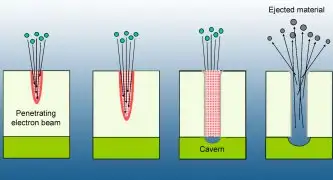

The high-power density in the focus the electron beam of 108 W/cm² and over also makes the electron beam ideally suited for drilling. A vapour capillary in the material builds up at the point of impact, and this is surrounded by a coat of molten material. This forms the basis of the hole.

Backing material

The backing material applied to the reverse side of the work piece being drilled is vaporised by the electron beam as soon as the work piece is penetrated. The emerging volume of gas expands explosively through the capillary and blasts out the molten material surrounding the capillary.

"Flying drilling"

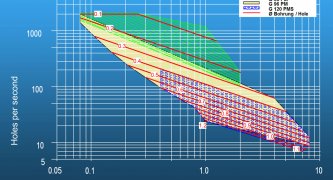

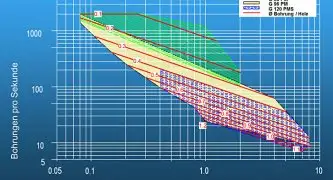

Flying drilling is not used by other methods (laser beam, EDM, ECM). Due to the combination of beam deflection, the movement of the work piece device and a control system adapted to the process, it is possible to move the work piece and the electron beam synchronously. During the drilling operation, the beam is simultaneously moved along the work piece surface. The beam is switched off between two drilling processes. At the next position the beam is switched on. The sequence of this procedure enables very high drilling frequencies.

Reproducibility

The electron beam is not moved and focused mechanically, but instead using electromagnetic lenses. The beam parameters and drilling parameters can be saved, which means the drilling process can always be reproduced.

Materials

Nearly all metallic materials can be processed with the electron beam, regardless of how hard they are. This also applies to alloys with a high thermal capacity.

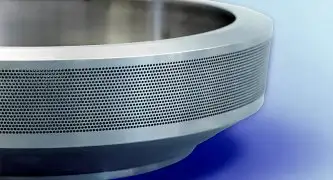

Drill holes

The EB perforation and the use of backing material gives the drill holes a characteristic shape. The edge at the beam exit point is always sharp and burr free. At the beam entry point, the drill-hole normally features a slight rounding.

Deutsch

Deutsch  English

English  Français

Français  Polski

Polski  Italiano

Italiano