With the local surface modification (often also "edge layer hardening") in selected ranges of workpiece surfaces, point-exactly and only where necessary, changed characteristics can be produced, as this happens e.g. with the hardening. With the exactly controllable electron beam a precisely defined amount of heat is applied within a very short time, which is necessary for a certain process. In this process, only near-surface zones are transformed (0.1 - 1 mm; sometimes more) and the structure of the component remains unaffected, resulting in minimal component distortion.

Another significant feature of the electron beam surface modification is that no separate cooling is required, as the heat dissipation into the solid component is sufficient.

Surface modification as part of EB technology has many possible applications - nearly in all areas of mechanical engineering, automotive engineering, medical technology, aerospace engineering and many more.

NC axes in the process: rotation, focus, deflection

51CtV: 4 oval cam tracks, hardness depth > 0.4mm

Processing variants

The electron beam surface modification

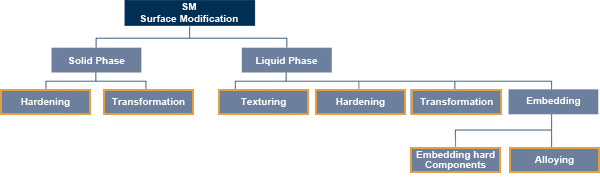

There are various process possibilities. A significant distinction must be made between processes that take place in the solid phase, i.e. without any melting of the surface, which can even be ground prior to this, and processes that go beyond the near-surface melt flow and thus enable significantly stronger property changes (but usually also require post-processing).

The following chart explains the possibilities for electron beam surface modifications. For further details please click the active buttons in the chart.

SM - Surface Modification

Solid phase

Hardening

Hardening is characterised as; heating up steel to the Austenitic temperature by the energy of the electron beam followed by rapid quenching – producing the structural form of Martensite (hardening structure). Martensite is required in steels to achieve a considerable increase in hardness. The achievable (Martensitic) hardness is directly dependent on the carbon content of the steel. The higher the carbon content, the greater the hardness.

Electron beam hardening can also be combined with a pre-executed thermo-chemical process, e.g. nitriding.

| Example: Transverse macro-section | Hardness profile measured from surface to base material HV 0.3 |

|

|

Transformation

With an appropriate dosage of the energy input, surface areas in the solid phase can also be converted locally and in a restricted area. The type and level of conversion depend on the metallurgical characteristics of the material. In the case of steels, tempering is an example: If necessary, it can also be used for EB hardened surfaces in order to limit a certain maximum hardness.

Liquid phase

Texturing

The electron beam melts the surface in smallest areas and forms unevenness, e.g. small saucers, etc., during solidification. These relatively simple textures can then give the surface a defined grip, for example, as in the case of rollers, etc.

More complex patterns with fast beam deflection (EBO Jump) lead to controlled evaporation, throwing up and redistribution of material. In this way, complex structures can be created, tailor-made for the specified requirements.

|

|

|

|

| Images of features made using the Surfi-Sculpt®-process, courtesy of TWI Ltd. | |||

Hardening

In order to achieve large hardening depths (about some millimetres) in ferrous materials, the surface can be melted locally. Self-quenching results in a structural change with a corresponding increase in hardness, e.g. as with martensite or ledeburite.

Due to the melting process, the workpiece surface becomes uneven and must usually be reworked. By using strip or dot pattern patterns during the EB process, it can be avoided that too large coherent areas are melted and too much unevenness is produced.

Transformation

Similar to liquid-phase hardening of ferrous materials, local structural changes can also be achieved in the microstructure of other materials. Especially with cast materials with their typical coarse-crystalline structure, grain refinement can be achieved which results in comparatively better wear characteristics.

|

Sample: Al-Si piston alloy Left: Cast structure, right: EB remelt structure (in the same scale) |

Embedding

Embedding hard composites

Hard composites in particular can be embedded locally into the surface of a component to increase wear resistance, if these are re-melted with the electron beam. With a moderate energy input, the hard particles remain in the remelting area; with a higher energy input, they are split and finely spread or even alloyed.

|

Embedded tungsten carbides |

|

Fused tungsten carbides |

Alloying

By adding other materials, e.g. by means of wire or a coating layer, into an EB remelting process, the treated surface area can be alloyed in a defined manner. This makes a specific change of the characteristics possible.

Deutsch

Deutsch  English

English  Français

Français  Polski

Polski  Italiano

Italiano