The advantages of the EB-technology

High precision and exact reproducibility

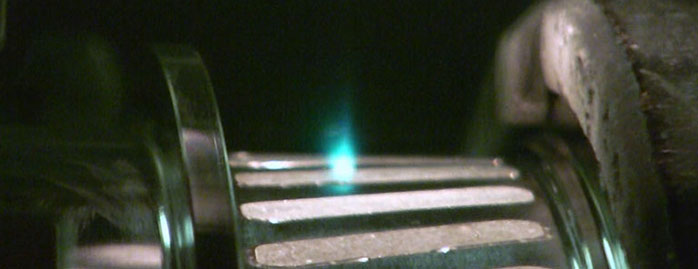

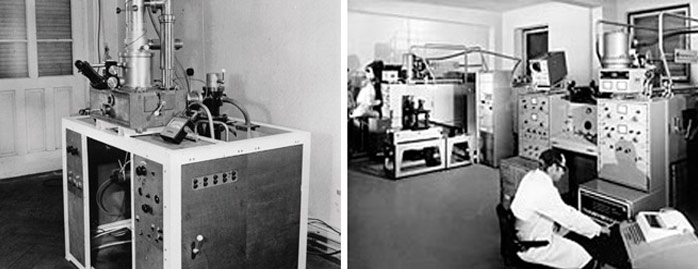

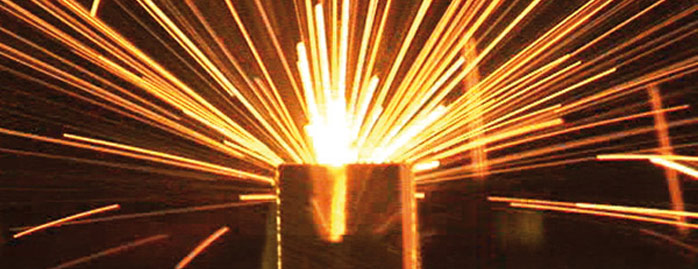

The stability of the small electron beam diameter in the focus is the basis for high geometrical precision. Almost all work parameters are controlled electronically and can be easily adjusted to changed tasks. This results in excellent reproducibility of the results from applications.

Deutsch

Deutsch  English

English  Français

Français  Polski

Polski  Italiano

Italiano