This type of electron beam machine is a universal design for tackling a wide range of welding jobs. The entire EBOCAM® system is modular in construction, both mechanically and electrically. The size of the machines depends on the requirements of our customers and ranges from chambers with a volume of a few litres to large chambers. The equipment is variable and chambers can be combined in almost any way with high voltage generators (150 kV) and low voltage generators (60 kV).

EB chamber machines are mainly used for single processing of large work pieces with complex welding seam geometry or processing areas.

Special size chambers are designed to order for individual electron beam applications.

Electron beam chamber machines are equipped with either a coordinate table (2 axes, x-y table) or a linear movement (1 axis, x-table), which are used to move the work pieces. It is possible to add to these basic movement systems rotating devices, tilting devices, customised mechanisms or any combination of these devices. Positional accuracy, as with tool machines, and movement systems with narrow speed tolerances ensure results of the highest quality.

Details

The basic equipment with an x-y table for moving work pieces and the machine’s control system can be complemented in a variety of ways:

- Work chambers from 0.5 to over 60 m3

- High voltage generators with up to 60 kW of power for working distances up to 1500 mm (without affecting the beam quality)

- Highest reproducibility and long-term stability of the beam parameters give consistent results

- Short cathode change times without subsequent adjustment of the beam position or parameters

- Additional positioning axes such as rotating, tilting or swivel devices

- Multiple work piece fixtures

- Special software for SPS or CNC control for quality assurance and documentation purposes

Operating data in detail

Standard connections and installation conditions:

- Mains supply: phase current 3 x 400 V ± 10 %, 50 Hz, PEN (if necessary, a mains supply transformer must be connected between the mains supply at the customer and our machinery)

- Lightening earth: < 3 Ohm, 35 mm2

- Input power and required power depends on the machine model (electron beam generator power, drive, pump set, ...)

- Compressed air: ≥ 6 bar

- Cooling water or water-cooling system

- Ambient temperature +12 °C to +35 °C

- Relative humidity, not condensing max. 70 %

- Avoid electromagnetic fields near the machinery

- Vibration-free installation position (normal factory conditions are sufficient)

- Floor loading: max 16 daN/cm2

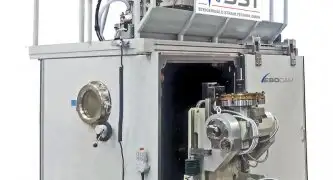

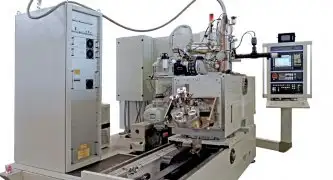

Pictures of delivered machines

- Chamber volume: 3.6 m3

- Working chamber: 1.6 m x 1.25 m x 1.8 m

- Generator: 150 kV / 15 kW

- Control: Siemens CNC

- 100218

- Chamber volume: 7.8 m3

- Working chamber: 2.7 m x 1.6 m x 1.8 m

- Generator: 150 kV / 15 kW

- Control: Siemens CNC

- 100215

- Chamber volume: 11 m3

- Working chamber: 3.2 m x 1.5 m x 2.2 m

- Generator: 150 kV / 15 kW

- Control: EBCON CNC

- 100129

- Chamber volume: 12.2 m3

- Working chamber: 2.9 m x 2.0 m x 2.1 m

- 2 generators each: 150 kV / 15 kW

- Control: EBCON CNC

- 100195

- Chamber volume: 15.9 m3

- Working chamber: 3.1 m x 2.1 m x 2.45 m

- Generator: 150 kV / 30 kW

- Control: Siemens CNC

- 100214

- Chamber volume: 18.1 m3

- Working chamber: 3.25 m x 2.1 m x 2.65 m

- internal Generator: 60 kV / 30 kW

- Control: Siemens CNC

- 100182

- Chamber volume: 22 m3

- Working chamber: 3.2 m x 2.5 m x 2.8 m

- Generator: 150 kV / 15 kW

- Control: EBCON CNC

- 100130

- Chamber volume: 54.4 m3

- Working chamber: 4.9 m x 3.7 m x 3.0 m

- Generator: 150 kV / 30 kW

- Control: EBCON CNC

- 100166

- Chamber volume: 45 l

- Working chamber: 0.3 m x 0.3 m x 0.5 m

- Generator: 60 kV / 6 kW

- Control: Siemens PLC

- 100120

- Chamber volume: 110 l

- Working chamber: 0.55 m x 0.45 m x 0.45 m

- Generator: 60 kV / 6 kW

- Control: Siemens CNC

- 100185

- Chamber volume: 220 l

- Working chamber: 0.6 m x 0.6 m x 0.6 m

- Generator: 60 kV / 6 kW

- Control: Siemens CNC

- 100156

- Chamber volume: 270 l

- Working chamber: 0.915 m x 0.55 m x 0.54 m

- Generator: 60 kV / 20 kW

- Control: Siemens CNC

- 100150

Deutsch

Deutsch  English

English  Français

Français  Polski

Polski  Italiano

Italiano