The main item of any electron beam system is the generator

The EB generator

In the beam generator the electrons are emitted from a tungsten cathode accelerated by 60 to 175 kV to approx. 2/3 of the speed of light and then focused onto the work piece as a beam with high power intensity. Here the electrons are slowed down and the beam energy is converted into heat.

Power flux intensities of approximately more than 1 kW/mm² lead to spontaneous vaporization of the material with the corresponding deep weld effect. SST EB generators can reach power flux densities of over 100 kW/mm² and thus open up a wide range of applications in electron beam technology.

The most important subassemblies of an EB generator

Beam head

The electron beam head contains an insulator, which is equipped with a high voltage cable connector. The so-called beam generating system, consisting of cathode, bias cup and anode, is integrated in the insulator.

- Tungsten strip-type filament

High emission density with long working life of the cathode. Easy cathode exchange. - Wehnelt cylinder (corresponds to a negative control grid)

Powerless, high dynamic control of the electron beam energy

Column valve

This subassembly contains the connection for a vacuum system that is required for the electron beam generator, the column valve, which separates the beam generating system from the chamber by means of a vacuum.

Turbo molecular pump set

Hydrocarbon-free high vacuum for a long cathode life

Viewing system

Amongst other purposes, the viewing system is used to adjust the electron beam’s focus point on the work piece in the chamber. In addition, the welding process inside the chamber can be watched. Whereas telescopic systems were previously used, camera systems are mainly employed now. Electron optical viewing systems are the most up-to-date development.

Electromagnetic system

The electromagnetic lens for electron beam focusing, as well as the deflection system are housed in this section.

SST electron beam generators for

| High- and soft vacuum machines: | 60 kV accelerating voltage and 1 to 45 kW beam power 150 kV accelerating voltage and 7,5 to 60 kW beam power |

| Non-vacuum welding machines (NVEBW): | 175 kV accelerating voltage and 1 to 30 kW beam power |

Application range for electron beam welding of steel materials in practice

| Welding depths: | 0.05 up to 200 mm and more |

| Welding speeds: | 0.5 up to 400 mm/s and more |

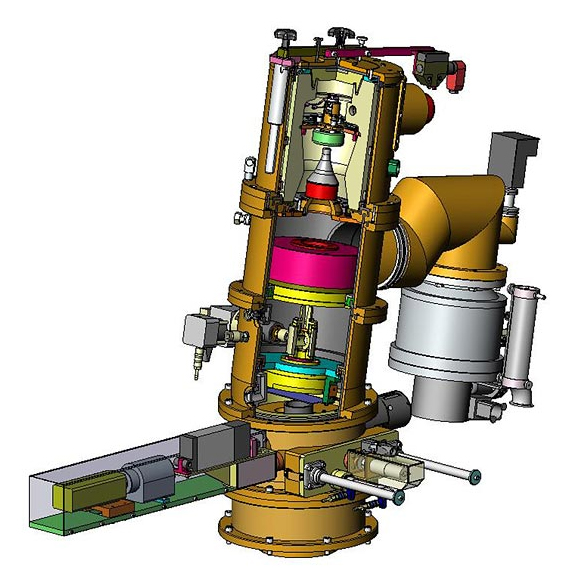

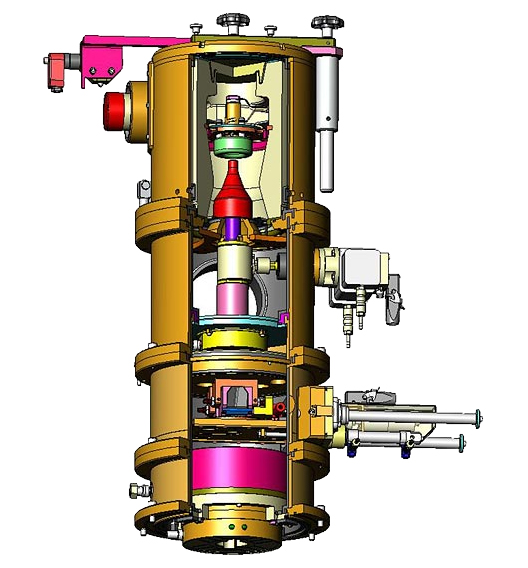

Electron beam generator

Electron beam generator with bend

Electron beam generator

Deutsch

Deutsch  English

English  Français

Français  Polski

Polski  Italiano

Italiano